1. The Design

All of our chillers are designed and manufactured at Drake Refrigeration, Inc. located in Bensalem, PA., USA. Each chiller order is individually processed by a team of engineers to ensure that we are providing the best possible product for each application. The type of chiller may vary in size, overall design, and industry served, but the process in which they are built is the same.

2. Bending

The metal is lasered or punched and deburred and the components come out as flat pieces. Most of the sheetmetal parts require being formed into a particular shape to establish a firm connection as a skeleton of the chiller. Bending is completed using a hydraulic press brake to form the metal with precision accuracy.

3. Assembly

The chiller metal infrastructure is securely fastened together using sheetmetal rivets, nuts and bolts, and anchors. The metal components are drawn in Solidworks so they come with pre-punched holes to mount components in proper positions and ensure no drilling is required.

Major Components

Once the chiller frame is finished construction the major components are then loaded. The four fundamental components that make up the chiller include: compressor, condenser, expansion valve, and evaporator. Also, loaded at this time are the suction accumulator, pump (s), and tank. All of these components are mounted to the chiller frame and the unit is sent into the piping station.

4. Piping

We have all the parts assembled and locked in, but we need to connect them all. That is where the copper tubes come into action. Copper tubes are the veins of the chiller, it connects all of the vital parts of the chiller and makes the unit work in a cycle and function as one. The reason why copper is the go-to material for pipes is because of its flexibility, durability and ease of installation. This process is time consuming, and requires a great deal of experience to figure out the best path for the pipes. Most units have pre-programmed pipe bends for use with both of our CNC Pipe Benders. This eliminates most of the braze joints from the chiller resulting is a more robust and reliable chiller.

5. Brazing

With the copper tubes fitted, the next step would be securing that connection by announcing their marriage in holy matrimony, so they can be together forever. That is where brazing comes in. Brazing is a metal-joining process by using a highly concentrated flame to heat up a filler metal between the joints of the pipes. The filler metal has a lower melting point than the pipes, thus when the filler metals melt, it is able to flow inside the gap between the pipes by capillary acition. Afterwards, the filler metal cools down and solidifies itself to the copper, creating a firm connection.

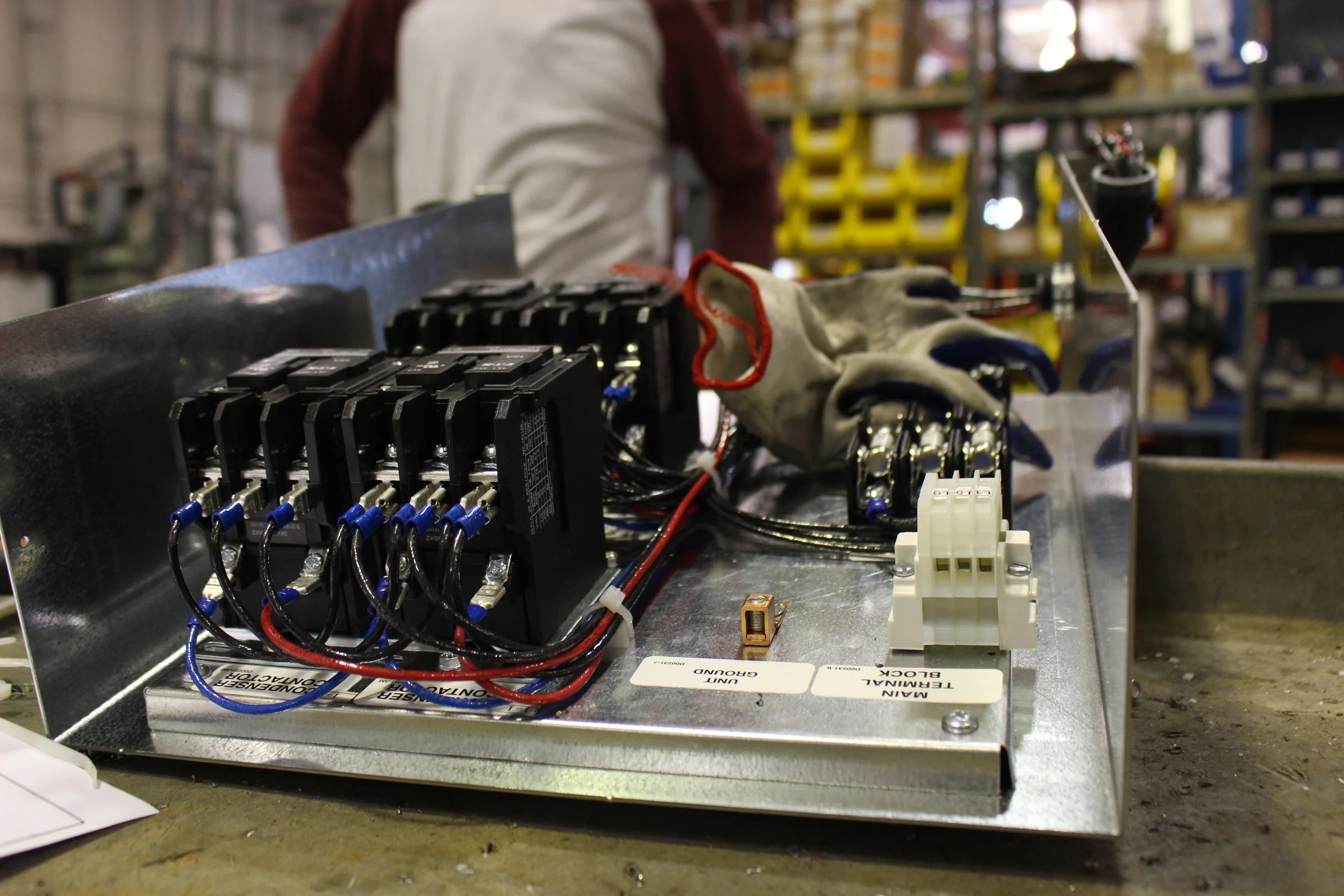

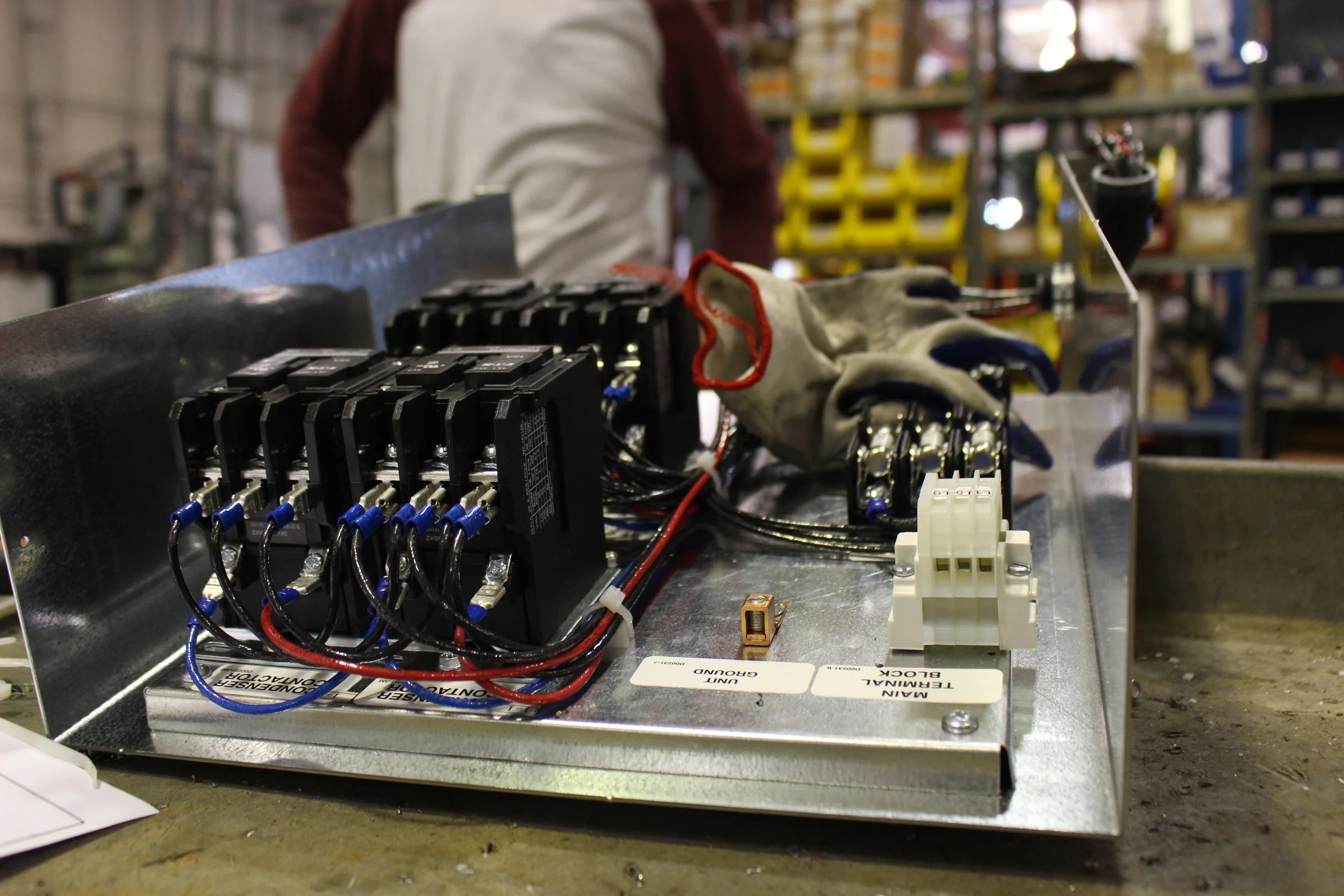

6. Wiring

Wiring is initially a separate process from the loading, piping and brazing. The panels are wired simultaneously with these processes. Wiring the panel can be fairly complex and requires precise measurement. The idea is to fit all the wires, interfaces, processors, microchips, and adapters into a metal box. Ultimately the panel ties in with the chiller prior to testing. This is where the panel is then fitted up to the unit and all major components are wired back to the panel.

7. Shipping

After testing, the chiller is ready for the customer. We carefully package each product to insure the safety of each chiller. Thus, when the chiller arrives to the designated location, the chiller is in the solid condition for cooling your process.